This is a cross-posting from my blog Robert's Reflections.

Setting the Scene

It was a sudden inspiration. But inspiration never came without a reason - Jo Nesbø, The Snowman (2010)

Norway can build tunnels incredibly cheaply compared to its international counterparts, as pointed out by Sam Dumitriu. The E39 Rogfast project, a 16.6 mile subsea tunnel in northern Norway began construction in 2023Q1 and is expected to be complete in 2029Q3. Once built, E39 Rogfast will be the world’s deepest and longest subsea tunnel. The cost is projected to be $1.8bn or $100m per mile; for comparison, Britain’s Channel Tunnel cost $469m per mile with Boston’s Central Artery/Tunnel Project, the Big Dig, a 7.5 mile long tunnel, costing $1.97bn per mile.

With almost 2,000 tunnels, Norway has perfected building tunnels at low cost. Their tunnels are so sophisticated, they even contain roundabouts, are among the safest in the world and comprise the world’s longest road tunnel, the Laerdalstunnelen at 15.24 miles. The Laerdal tunnel has been developed with a view to creating a pleasurable driving experience: its lighting mimics a sunrise. Norway’s Transport Plan (2022 - 2033) promises to build even more tunnels. Norway’s inspired building of tunnels deserves careful study as it reveals ways in which the rest of the world could begin to build similarly cost effective tunnels.

The Laerdal Tunnel

Drilling Deeper

Wise men learn by other men’s mistakes, fools by their own - Norwegian proverb

Norway did not have a headstart in tunnelling. The first European road tunnels date to Rome’s Furlo Pass from the 3rd century BC. The technology required regressed throughout the Dark Ages and the Mediaeval Era with few extant examples remaining besides Bavaria and Austria’s erdstallen, small tunnels built for escape purposes. Only with the Industrial Revolution did Norway begin to experiment with tunnels.

Erik Engheim notes that during the 19th century shipping sugar from Havana to Oslo by sea was cheaper than transporting sugar 35 miles from Oslo to Eidsvoll by horse and cart over Norway’s mountainous terrain. For instance, north of Oslo lies Hardangervidda, Europe’s largest mountain plateau, traditionally a significant barrier to connecting the capital in the far south with the rest of the country.

The steam age and its dynamite offered a way in which man could tame mountains. Going through a mountain was a much more direct path than traversing its humps and bumps by horse and cart. Though modern Norway has the world’s third highest GDP per capita, primarily due to the discovery of hydrocarbons in 1967, it was relatively poor compared to its European counterparts in the 19th century. This forced Norwegians to develop tunnelling technology cost effectively, a feat realised through the Bergen railway, completed in 1909, which connected the east and west of the country with the help of 182 tunnels.

Hardangervidda

Norway’s mountains generally consist of hard rocks such as granite or gneiss. The initial approach to tunnelling was the drill and blast method: drilling holes in the rock, loading them with explosives, and detonating. Norway’s geology provided an impetus to innovate further and develop the Norwegian Method of Tunnelling (NMT). The Norwegian approach combines drilling and blasting with the Q-system, where Q stands for Rock Tunnelling Quality Index, used to identify where rocks can provide natural support. When needed, shotcrete, a form of spray-on concrete, is used to enhance support and to construct Reinforced Rib Shotcrete structures through a single shell of support. Sequential excavation is used, drilling a tunnel in separate stages, which allows for more discretion on where additional support such as bolts are provided.

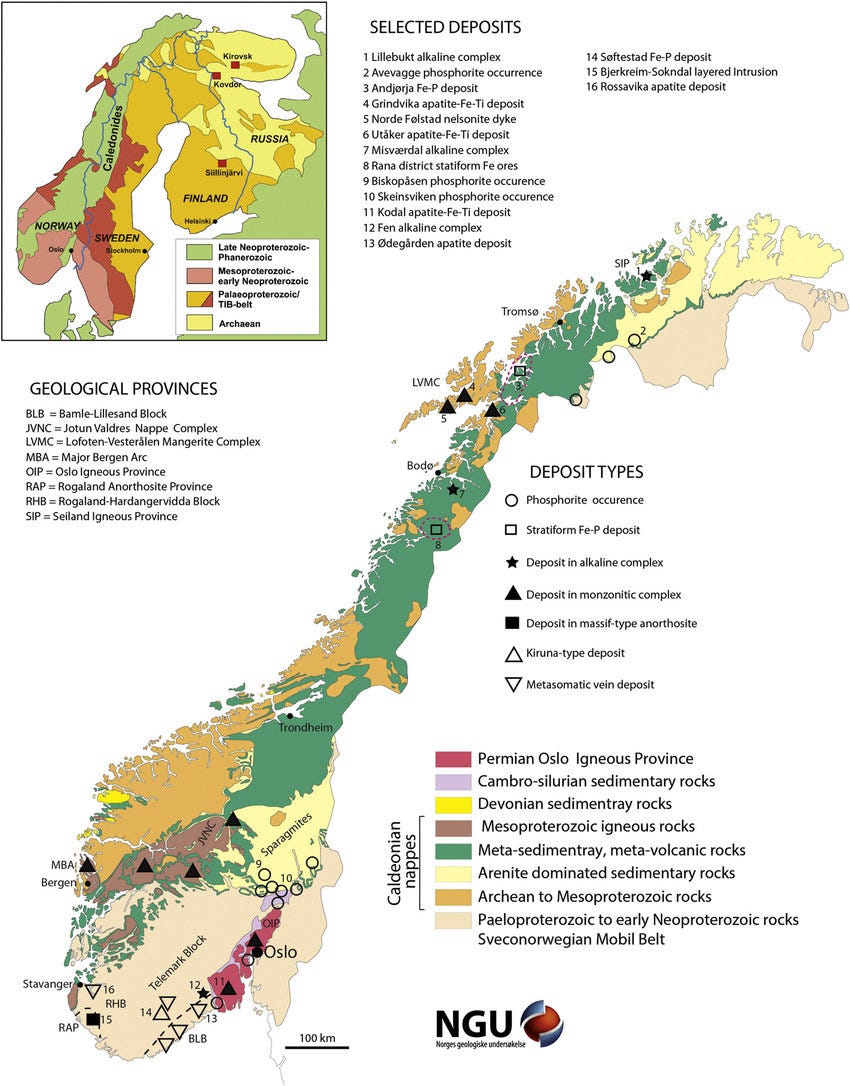

A Geological Map of Norway

An alternative to NMT is the New Austrian Tunnelling Method (NATM), originally used for weak ground and used to build the Channel tunnel. The Austrian method applies shotcrete after excavation and then provides more support through anchors and bolts - a double shell support system. Though NATM is more flexible and suited to a wider variety of rock types, the doubling of support is associated with higher costs that do not necessarily translate into increased safety. In countries such as the UK, oscillating between hard and weak rocks, NAMT is the default option due to the perception it is the safest method available. In such cases, one way of reducing the cost of tunnelling is to use a hybrid between NMT and NATM. This would involve using sequential excavation as an opportunity to alternate between single and double shell support as has been successfully implemented in India.

The Laws of Jante

By means of Jante Law’s ten commandments, Jante holds Jante down. And now you must hear them all - Aksel Sandemose, ‘A Fugitive Crosses His Tracks’ (1933)

As Dumitriu points out, a large proportion of infrastructure construction costs in the UK are due to bureaucracy - the mere application to build a tunnel in Britain costs more than actually building one in Norway. The administrative steps involved in tunnel construction in Norway as outlined by the Planning and Building Act (2008) include:

Needs and feasibility assessment

- Environmental impact assessment

- Geological surveys

- Design and engineering

- Cost-benefit analysis

- Public consultation

- Government approval

- Funding allocation

- Contractor selection

- Safety and construction planning

- Ongoing monitoring and assessment

At first glance, these steps are not too different from the US or UK. However, the final step is a deviation from both jurisdictions as community engagement is spread out over the lifetime of a project. In contrast, the Anglophone approach is front-loaded with public involvement only in the consultation stage; once a project is built in the US or UK, there is typically no opportunity to voice concerns in a way that could affect change outside of a legal setting. In essence, Norway maximises public involvement in the design, implementation and future of its infrastructure. Sam Bowman’s argument that democracy is an antidote to vetocracy finds empirical support in Norway where Not in My Backyard (NIMBYism) is therefore generally not an issue (except for wind farm proposals).1

Norwegian social norms also appear to be more conducive to consensus building. Taking the Janteloven, the laws of Jante, a set of social codes originating in fiction that have come to encapsulate much of Norwegian culture include:

- You’re not to think you know more than we do.

- You’re not to think you can teach us anything.

Both of these laws would be broken by the average NIMBY. Though Janteloven was proposed by Aksel Sandemose as a critique of Nordic conformism, he unwittingly unearthed a fundamental reason why bureaucracy is not a bottleneck in Norwegian infrastructure provision. No Norwegian wants to be the one to break from the herd and lodge an objection.

Spreading a culture of conformity is difficult and likely impossible to export to the US and UK, where breaking from the herd is preferred, and so the critical lesson is the importance of incentives. The opportunity for the public to give their feedback on a project after its completion leads to higher and more constructive engagement. Critics of conformity argue it stifles innovation, but this is not true in the Norwegian case. NMT is truly original from an engineering perspective.

Boston’s Big Dig was constructed using cut-and-cover, excavating a trench, building the tunnel in it and refilling the trench. Taking over two decades to build, from 1991 until 2007, having first been proposed in the 1970s, the Big Dig is a case study in how not to build tunnels. Initially estimated at a cost of $2.56bn, roughly half of the cost growth was attributable to inflation which was passed on to the taxpayer through the Federal Acquisition Regulation by the primary contractors Bechtel Corporation and Parsons Brinckerhoff.

The complexity involved in the Big Dig required over 200 subcontractors and a lack of institutional oversight led to numerous instances of fraud as unearthed by the Federal Bureau of Intelligence and the US Attorney’s Office. Criminal conduct related to the project consisted of overbilling such as using substandard materials and charging the taxpayer for higher quality ones or simply misstating project costs. Repairing the results of substandard work due to the use of cheap materials also extended construction time and costs. Auditing such projects takes a decentralised approach in the US with a mixture of federal and state agencies responsible for ensuring public funds are correctly spent. Over the lifetime of the Big Dig, the Massachusetts State Auditor’s Office was tasked with reviews of the project focused on specific issues, rather than a comprehensive overview, which led to room for fraud. At the federal level, the Government Accountability Office performed audits only after issues had been escalated and the damage to the taxpayer’s purse was done.

Norway does not allow contractors to pass on cost overruns to the taxpayer for all government contracts which incentivises finding cost efficiencies. Instead, government contracts are either fixed-price, with work completed for a predetermined amount, or cost-plus where the government absorbs the actual cost plus some fee for work done with specific clauses handling how inflation is absorbed by the taxpayer. For large projects, the Norwegian parliament mandates the initial project cost of a project with auditing centralised in the Office of the Auditor General of Norway. This leaves little room for gaming the public contracts system.

Norwegian project management is streamlined: a single reporting line ensures effective coordination and cost management. Boston’s Big Dig consisted of two reporting lines for much of the construction process, with some employees reporting to government agencies and others to Bechtel and Parsons. Only in 1998, far behind schedule, was the reporting organisation integrated. A lack of institutional foresight and capacity can be blamed for the cost overruns for the Big Dig. Skanska is the main contractor for E39 Rogfast and has been steadily increasing its share of contracts in the US and UK, including some tunnels in the former, so purchasing Norwegian tunnelling expertise is an option for other countries.

Conclusion

Norway’s development of an innovative tunnelling method combined with its culture and institutions ensures projects can be completed cheaply. NMT reduces costs, the state minimises vetocracy through public involvement and leaves little room for abusing the taxpayer through the public procurement process. Other countries could learn these lessons.

1 I hope to address the long-running battle between wind farms and the Sámi people of Norway, and its lessons for the Progress movement, in a later post.