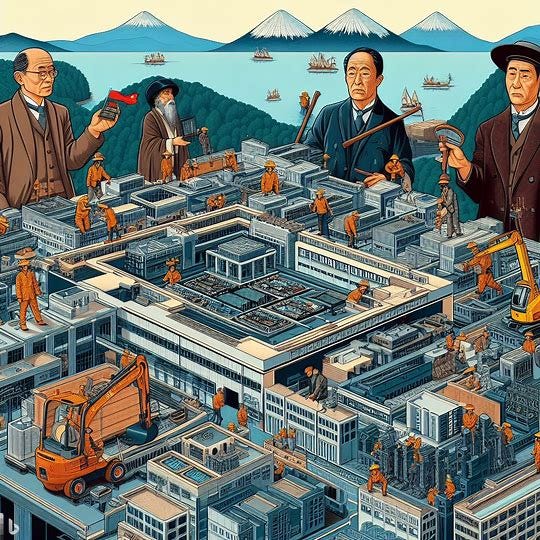

Suddenly, Japan was open to the world. In 1868, the conservative, isolationist shogunate that had ruled the country for two and a half centuries was overthrown by a group of enlightened revolutionaries seeking to re-empower the emperor and modernize the country.

We call this event the Meiji Restoration and the regime it ushered in embarked on a swift and historic effort at industrialization. But it did not attempt to do this on its own. At first, the government employed a small army of Western experts, including former European bureaucrats and businessmen, to staff its government agencies and state-owned firms:

In the early years of Meiji, the new government hired from 300 to 600 foreign advisers in any year on a project contract basis, at considerable fiscal cost, to establish Western-style state-owned enterprises in railways, telegraphy, and silk reeling (Umetani, 1968). Some foreign advisers received salaries higher than that of the Japanese prime minister. Each project recruited a team of foreigners, usually of the same nationality, with various functions, who imported virtually all the materials required to create an exact replica of a foreign model (Kasuya, 2000). These were turnkey projects with a foreign director supervising his fellow countrymen and Japanese workers, with the Japanese side taking over operation and maintenance after project completion.1

Skilled Japanese workers, over time, would learn from these projects, allowing the country to climb up the value chain and engage in more sophisticated manufacturing. Foreigners staffed key posts at high-tech firms in the early days of Japan’s opening up, but only at first. In mere decades, the country became a preeminent economic and military power. The rapid advancement of Japan’s military might and industrial capacity enabled the country, in 1905, to shock the world by defeating the Russian Empire in the Pacific.

Japan’s new leadership was attempting to answer a question that both bureaucrats and industrialists alike have contemplated for generations: How does a country build industries in which it has no particular expertise?

We call a strategy to answer this question “industrial policy.” Wrong answers to this question have resulted in humanitarian catastrophe. The best answers have coincided with historic reductions in hardship and poverty.

For decades, industrial policy has largely been the domain of developing countries seeking catch-up growth through manufacturing, but as the world re-fractures into competing economic blocs, rich countries are getting back in the industrial policy game, too. Getting it right means drawing on the two centuries of lessons from past experiments. And if there is one lesson that stands above the rest, it is the indispensability of foreign expertise.

The temptation of industrial policy is nearly irresistible. After all, the goal from the start is merely to replicate the kind of manufacturing happening in many other countries across the globe, not necessarily to break new ground or invent new technologies. How hard could that be? Imitate, then innovate.

Advocates have a broad toolkit for channeling credit, subsidies, and educational institutions towards building up the target industry of choice, perhaps auto manufacturing, steelmaking, or microchips. Industrial policy may be hated by most market fundamentalists, but successful cases harness the unrivaled discipline of markets. Countries like South Korea pushed top firms in nascent industries like auto manufacturing to compete (export) in global markets, where competition is most fierce. Kept alive by state support while facing technologically superior foreign firms, Korean conglomerates learned from their competition and were eventually able to stand on their own.

Yet it is important to remember that for all the attention to the virtue of “export discipline,” perhaps deserved, industrial policy success stories are fundamentally about people learning how to do new things from other people. Industrial policy has always been linked to immigration policy or the utilizing of foreign expertise, which many advocates of the former fail to see today. Foreign experts from countries at the technological frontier have been indispensable to developing nations chasing catch-up growth, imparting the kind of deep, tacit knowledge one can only impart face-to-face. Those who try to summon advanced manufacturing sectors from the ether inevitably fail. As Joe Studwell writes of post-War China and India in the throes of strict autarky: “Each time firms wanted something new they had to, as the saying goes, reinvent the wheel.”

Industrial take-off is hard under the best of circumstances. Starting from scratch is insanity.

For perhaps the most famous example of foreign-born scientists and inventors getting a nascent industry off the ground in a new country, look to American aerospace.

As Brian Balkus (another Roots of Progress fellow) writes in Palladium, American efforts to steal information and documents on Nazi Germany’s rocket program bore little fruit. U.S. officials discovered that capturing technical information was insufficient for reverse-engineering and harnessing Germany’s breakthroughs for themselves. Instead, they needed the actual experts working on the program.

This would evolve into Operation Paperclip, in which hundreds of German scientists were brought to the United States to build an American aerospace program. This turned out to be the talent coup of the century, forming the backbone of both NASA’s space program and an immensely productive aerospace manufacturing sector.

“There are huge chunks of technical knowledge that cannot be acquired by reading texts,” Balkus writes, “And history has shown that it is only possible to access this knowledge through the humans who possess it.” Failure to understand the nature of information necessary to produce some of the world’s most sophisticated technologies–and how people actually learn it–has been behind many failures of industrial policy. Again, the example of aerospace is instructive:

Aerospace is one of the deepest branches of humanity’s technological tree. It is a telling fact that more countries have produced a nuclear bomb than have mass-produced a jet engine. Recent history illustrates how hard it is to build these capabilities. China has provided an estimated $71 billion dollars in funding to the Commercial Aircraft Corporation of China to develop a competitor to Boeing and Airbus, and 15 years later it has barely begun to produce its first operational commercial airline even while its engines, avionics, and other core systems are imported. In Japan, Mitsubishi Heavy Industries spent 15 years and nearly $8 billion attempting to build Japan’s first passenger jet before killing the project in 2023, stating “We didn’t have engineers with such know-how, and it was rather [hard to find] any in Japan.”

Successfully replicating jet engine production domestically is a Herculean task in the most generous and supportive policy environment. Attempting to do it alone is nearly impossible. As the United States and our allies usher in a new era of industrial policy targeting a set of key technologies, we cannot forget this lesson.

Immigration policy is a central tool in great power competition. Let’s use it.

At my day job with the Economic Innovation Group, I recently co-wrote a proposal with my colleague Adam Ozimek for a Chipmaker’s Visa, an immigration reform to pair with Congress’ $52 billion investment in semiconductor manufacturing and research. As we point out, just as American-educated members of the Taiwanese diaspora were critical to the early days of TSMC and its accompanying supply chains, so too will workers and managers at top firms in Taiwan, South Korea, Japan, and elsewhere be key to rebuilding our domestic chipmaking capacity today.

The United States remains the world’s top economic and political power, but there is increasing evidence that we are lagging behind our chief geopolitical adversary in key technology areas. Whether here, in allied countries, or in a combination of the two, the next decade of international economic policy will prioritize building resilience and bypassing Chinese Communist Party-controlled production chokepoints. There may even be further, expensive sequels to the CHIPS and Science Act for other industries Congress deems strategically-significant.

Regardless of whether you favor the kind of heavy-handed approach embodied by the CHIPS or something more light-touch, the importance of talent with on-the-ground experience and practical expertise cannot be ignored. We need to get serious about attracting the world’s top young scientists, engineers, and innovators, particularly those who specialize in areas of technology in which we will most intensely compete with adversaries. Without them, even our boldest and most well-designed industrial policies may flounder.

Consider the aggressive new efforts by the Chinese government to bring home Western-trained scientists and engineers in areas deemed critical to geopolitical competition. The government is offering generous subsidies for purchasing homes and bonuses of half a million dollars or more for Chinese experts returning to work in critical industries. Meanwhile, those same scientists and engineers recruited by U.S. firms to build out our semiconductor, artificial intelligence, or materials science industries could face a wait time of nearly two decades. Being a much freer, more open society certainly gives us some leeway here, but if we allow our skilled immigration system to deteriorate further, we will lose more top scientists, engineers, and inventors to our adversaries.

The proper financial tools to wield as we chase technological superiority over China in critical fields may still be up for debate. Ambitious industrial policy with extensive state intervention on behalf of our national economic interests–and claims about what those interests actually are–deserve a healthy dose of skepticism. But there is one thing that should not be up for debate: the United States needs major skilled immigration reform if we are to maintain or recapture global technological leadership. While the sprawling factories whose construction industrial policy aims to spur may be home to immensely complicated machinery and equipment, it is ultimately brains that make them work.

Subscribe to my blog at regions.substack.com if this post interested you!