Following the approval for the building of the World Trade Center in 1962, the Port Authority created a new department headed by Guy Tozzoli to manage the project[1], and began to search for an architect.

The Port Authority felt that because of the size and scope of the trade center it wasn’t just dealing with a normal construction project, but “the most important architectural project in New York, if not the world,” a project of “historical significance.”[2]

Due to its great size and scope, the proposed World Trade Center in its realization has the inherent power to create a great impact on man’s architectural thinking. Its planning, design, and construction should therefore represent man’s highest ideals, imagination and creative ability. Through full application of all his knowledge, he can build efficiently and economically a great constructive symbol of international trade in the Port of New York.

Such a project demanded an architectural masterpiece, and the Port Authority limited the search to architects it felt were capable of delivering. A list of 15-20 architects (which included some of the most famous names in architecture), was narrowed down to of seven finalists:

Carson, Lundin & Shaw

Philip Johnson

Walter Gropius’ The Architects Collective

Kahn & Jacobs

Minoru Yamasaki Associates

Welton Becket Associates

Kelly & Gruzen

(Mies van der Rohe had been ruled out due to age, and would die before the trade center was completed. IM Pei had been solicited but declined to participate. Several other famous architectural firms, such as Harrison & Abramovitz of the United Nations Headquarters, and Skidmore Owings & Merrill, had been part of an early advisory committee for the project, but its members had been eliminated from consideration for reasons that remain unclear.)

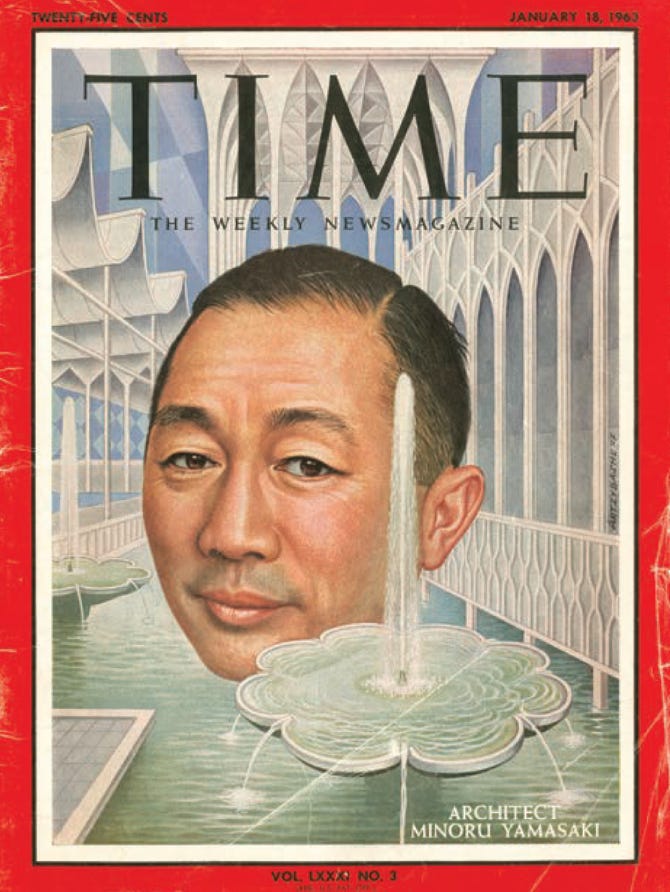

Four of the finalists were eliminated for being “insufficiently creative,” Philip Johnson was eliminated for arguing against the grandiose vision of the project (and embellishing his involvement in previous skyscraper projects[3]), and Gropius was eliminated after it became clear that his staff, rather than him, would be doing most of the design. Ultimately chosen was Minoru Yamasaki Associates, a small architectural firm located outside of Detroit. Yamasaki himself had achieved minor architectural renown for his design for the US Science Pavilion at the 1962 Seattle World’s Fair (photos of it appeared in both Time and Life magazines), and was most well-known for designing small-scale, highly detailed buildings. His only skyscraper projects were the 28-story Michigan Consolidated Gas Company Building in Detroit and the 20-story IBM building in Seattle, neither of which were complete when the Port Authority was making its selection. But the Port Authority liked his approach for the Trade Center[4], and Tozzoli had been enthusiastic about Yamasaki’s science pavilion design.

Because Yamasaki’s firm was so small (Yamasaki had originally thought the $280 million budget for the project was a typo with an extra zero), and based outside New York, the Port Authority also hired Emery Roth and Sons, a New York architect notable for designing unremarkable but extremely space-efficient buildings, as associate architect.

The pairing of Roth and Yamasaki is an interesting one. While Yamasaki was chosen to produce an “architectural triumph”, Roth’s professional motivations were quite different:

The Roth firm tended to be loved by builders and developers but ignored by architectural tastemakers because its architects did not pretend to be artists: “Ours is not a field of architecture in which we create or try to create masterpieces,” said Roth. “The entire endeavor in our office is to create the best that can be produced within the restrictions that are placed upon us,” - Minoru Yamasaki: Humanist Architecture.

Roth’s statement brings to mind the motivations of Shreve, Lamb, and Harmon in designing the Empire State Building, with Lamb stating “Whatever “style” it may be is the result of a logical and simple answer to the problems set by the economic and technical demands of this unprecedented program.” Emery Roth and Sons would later be the lead architect on WTC 7, which was built in the 1980s by a private developer.

The commission raised Yamasaki’s profile even further, and he appeared on the cover of Time in January of 1963 (the 11th architect to make the cover). Unfortunately, being awarded the project seems to have been disastrous for him personally. A year prior to his being selected as the architect he had divorced his wife of 20 years as “not his intellectual equal,” and over the course of the project he entered two more marriages (both of which ended quickly). He began to drink heavily, and was hospitalized following a seizure, falling in love with one of his nurses (who he later moved in with), and becoming addicted to morphine. He went on to remarry his first wife in 1969.

While the Port Authority was selecting an architect, it also navigated another obstacle for the project. Clearing the 16-acre site involved removing existing residents, many of whom didn’t want to vacate. A group of electronic retailers (known as Radio Row) formed the Downtown West Businessmen’s Association (DWBA). Led by Oscar Nadel (who had been partly inspired by Jane Jacobs speaking against the project), the DWBA organized opposition and protests (including one where Nadel laid in a coffin representing the death of “Mr. Small Businessman”), and filed a lawsuit in 1962 challenging the Port Authority’s use of eminent domain to evict the residents. In February of 1963, the court ruled against the Port Authority but was overturned on appeal, and the US Supreme Court declined to hear the case.

The twin towers concept

The Port Authority wanted its architectural triumph, but it also wanted a functional, economic office building delivered on time and under budget. Early on Yamasaki and the rest of the design team were informed by Mal Levy, design lead for the Port Authority, that “we can’t afford a corporate status symbol. This is not a trophy we are building. It is a speculative office building,” and received a cost target of 22 dollars per square foot (the entire project would ultimately cost more than a hundred dollars per square foot when it was completed in the 1970s). But upon viewing Yamasaki’s initial concept of a series of smaller buildings, the Port Authority was disappointed, with Levy stating, “We do not want just to create another office building development in Manhattan. Nothing here looks distinctive. Nothing here matches the approach that the Port Authority wants to take…The Port Authority wants this to be the most dramatic project in the world. It must be a symbol of New York.” Yamasaki would struggle with this tension (which exists, to some extent, on most building projects) between architectural vision and the more prosaic aspects throughout the project.

It’s worth briefly noting that the Port Authority was not a typical real estate developer. Though it hired an architect, a team of engineers, and a general contractor to design and construct the trade center (like a typical developer would), the Port Authority had its own team of heavily involved architects and engineers. And some parts of the project, such as the foundation system, would be designed and built by the Port Authority.

Yamasaki spent most of 1963 coming up with the basic design of the project, going back and forth with the Port Authority through more than a hundred different concepts:

He [Yamasaki] tried a rectangular slab in a large empty square; he tried a square tower in the center of a plaza with a low three-sided auxiliary structure ringing it. He tried two rectangular slabs in an empty square, and two backed by a low auxiliary building. He tried three square towers of differing heights set asymmetrically in a square; he tried three square towers of the same height…He tried four identical square towers…he tried four square towers of varying heights…He tried five towers…He tried over 100 schemes, and for each one he built a model and considered it from all angles…Somewhere between the 20th and the 40th attempt the twin tower concept emerged.[5]

The proposed twin towers were originally 80 stories tall, but by then the Port Authority (on the advice of their PR office) had decided that the trade center buildings should be the tallest buildings in the world. By extending them to 110 stories, not only was the desired space of 10 million square feet achieved, but the “tallest building in the world” goal was achieved as well. Roth advised the Port Authority that the extra height would mean exceeding the budget, but, as with the Empire State Building, the Port Authority believed the PR value of building the tallest building in the world was worth the added cost.

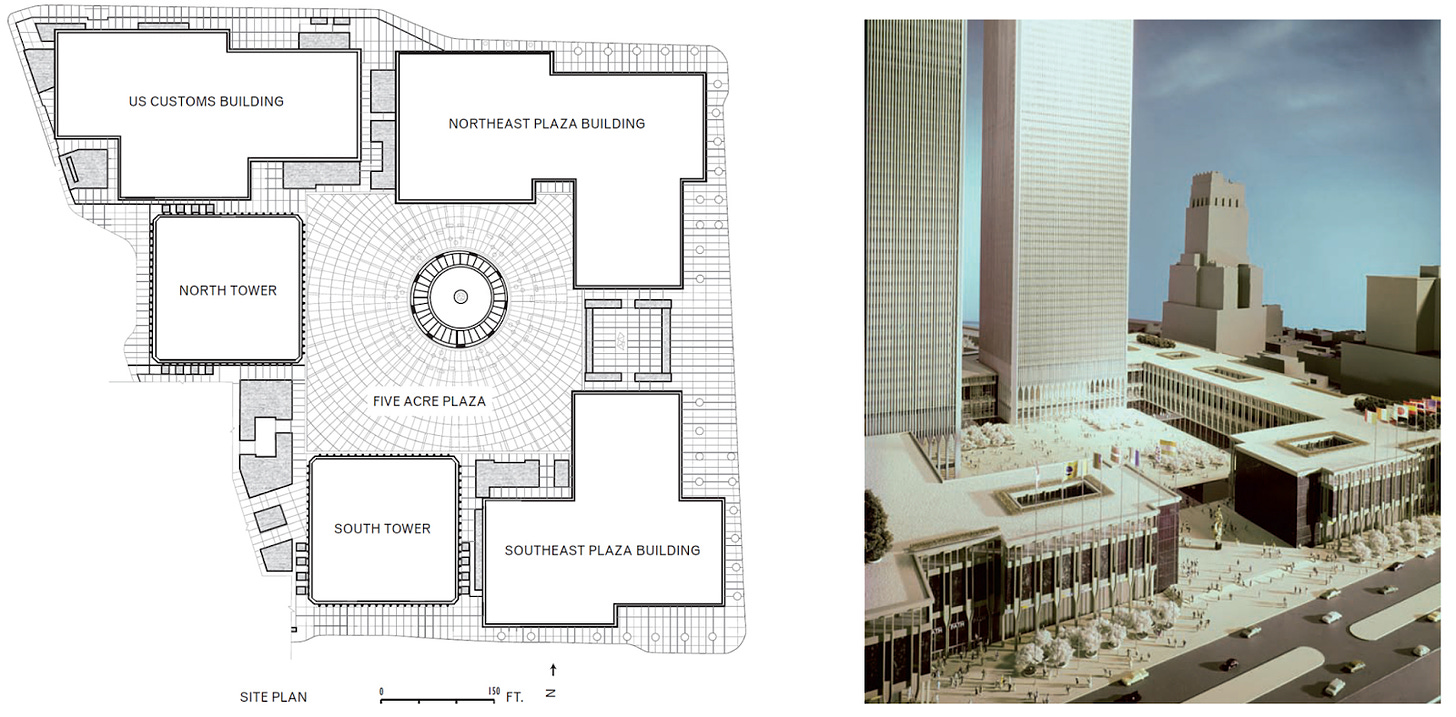

The design was officially unveiled early in 1964. Multiple existing city blocks would be combined into a single “superblock,” with two 110-story towers and a series of smaller buildings arrayed around a 5 acre plaza[6]. The new PATH station would fit below ground, along with a concourse with retail and restaurants and a 2000 car parking garage. The cost estimate for the project continued to climb, and by 1965 would hit $525 million.

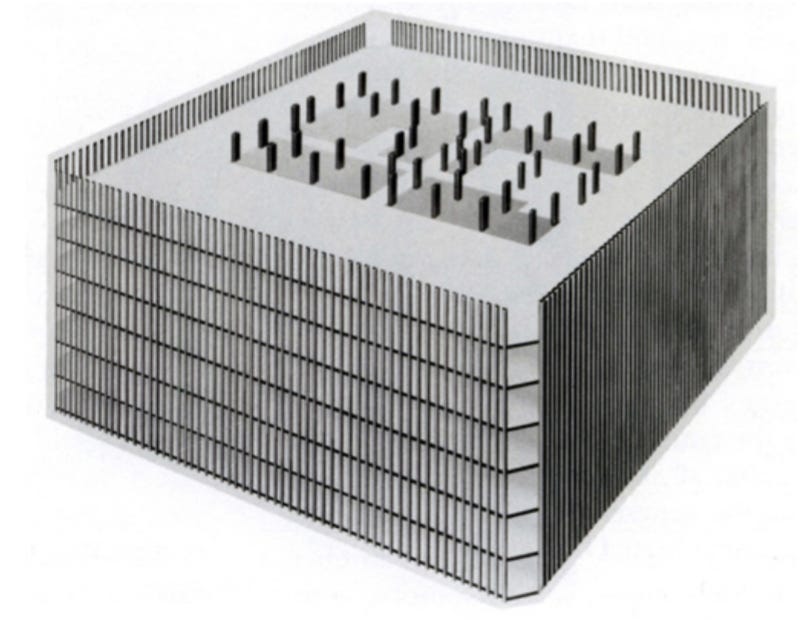

Once the basic concept for the project was established, the architects and engineers went to work on turning it into a fully specified design. There were numerous design challenges to solve, particularly with the structural aspects of the towers. Most skyscrapers used a structure of steel beams, supported on an array of steel columns spread throughout the building. This resulted in columns intruding on the usable space of the building. Yamasaki, however, wanted the floors to be open and spacious, with as few intruding columns as possible. To achieve this, Yamasaki and his favored structural engineer, John Skilling of Worthington, Skilling, Helle & Jackson[7] came up with the stiffened tube concept. Instead of columns spread throughout the building, the building would be supported by a series of tightly spaced columns on the exterior, and a load bearing structural core, with wide open spaces free of columns in between. The exterior columns would be stitched together using steel spandrel panels, which would allow them to serve as lateral force resistance for the building.This technique would eliminate the need for interior lateral bracing and result in extremely narrow windows, creating a distinctive look that would depart from the typical “glass box” of the international style skyscraper. Yamasaki, once an enthusiast of this style, had moved away from it, stating that, "For me, the day of the all-glass building is finished.“ He also believed (influenced by his fear of heights) that windows narrower than shoulder width were more comforting to occupants of tall buildings.

The stiffened tube system was brand new, used on only two other projects - the 43 story DeWitt-Chestnutt building in Chicago, and Yamasaki’s own 20 story building for IBM in Seattle, both of which were still under construction.

The floors would consist of large steel trusses supporting a composite metal deck, another novel system for a skyscraper (though similar trusses were common on warehouses and industrial buildings). To further reduce the amount of steel needed, the Port Authority specified that the structure should be welded, rather than bolted. Altogether, this structural system used an estimated 40% less steel compared to a more conventional skyscraper design.

But by omitting much of the interior structure and partition walls, along with other heavy building elements (such as stone cladding on the exterior), a new problem was created. Even with the stiffened tube structure, the building was significantly less stiff, and would sway much more, than previous tall buildings. The fact that the building was wide and maintained that width over its full height also contributed to the problem. Measurements of the Empire State Building showed that the top moved less than 4 inches in 80 mile per hour winds, but initial calculations for the World Trade Center towers suggested they would sway several feet or more.

A series of tests were conducted in 1964 to determine how much a building could sway before occupants noticed - a room was mounted to a series of hydraulics, and moved back and forth in a simulation of how much the trade center towers were likely to move. Not satisfied with these results, the Port Authority conducted its own series of tests, where a room was suspended by cable in the ventilation towers and swung back and forth.

Both tests showed that occupants were sensitive to surprisingly small amounts of motion. After extensive design work and wind tunnel testing, the engineers were able to reduce the amount of sway with viscoelastic dampers between the trusses to the exterior columns, and by adding a large “hat truss” at the top of the towers which tied the sides of the building together. But the Trade Center would still sway more than twice as much as the Empire State Building.

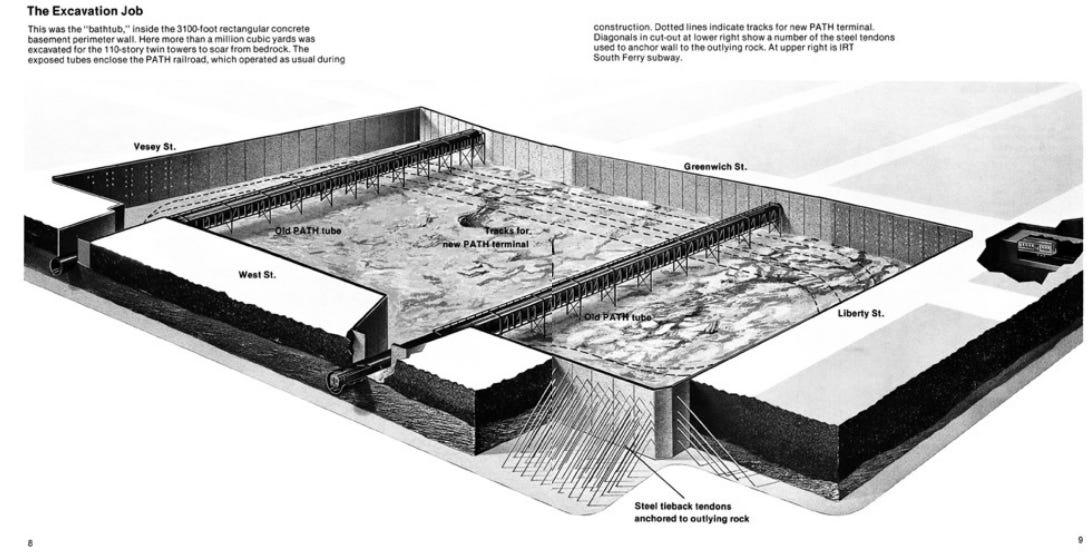

The foundation of the project presented its own series of design challenges. Large skyscrapers in Manhattan are supported on bedrock, the depth of which varies depending on your location. While at Rockefeller Center, the bedrock is only 8 feet below grade, at the World Trade Center site it’s 70 feet below grade. Excavation would be needed not only for the towers themselves, but for a large fraction of the entire 16 acre “superblock” which was being created. Altogether 1.2 million cubic yards of material would need to be removed from the site (by comparison, the amount of material removed from the Empire State Building site, including the debris from the existing Waldorf Astoria hotel, was about 110,000 cubic yards).

And once excavation began, water from the Hudson River would begin to rush in. If it were pumped out, it was likely to drop the water table, which might undermine the foundations of surrounding buildings. To solve this problem, the Port Authority constructed a large slurry wall (which became known as “the bathtub”) around the outside of the site. It was built by digging a 3-foot wide, 70-foot-deep trench that was filled with a viscous clay called bentonite to prevent the sides from caving in. Once the trench was dug, it would be filled with concrete, which would displace the bentonite. The process would then be repeated 158 times to create a 3294-foot-long wall around the perimeter. Once the wall was done, excavation of the inside of the “bathtub” could take place.

This method of excavation was common in oil and gas drilling, and had been used for subway construction, but it was largely unknown for building construction. No US contractors were familiar with the system, so the Port Authority hired an Italian company, Impresa Costruzioni Opera Specializzate, to construct it.

To reduce the space that the elevators would occupy, an “express” and “local” system of elevators was used. To reach the upper floors, people would take an express elevator to sky lobbies on the 44th and 78th floor, where they would transfer to a “local” elevator serving a smaller number of floors. Because the local elevators could share elevator shafts, this reduced the number of shafts required.

As the design progressed, Yamasaki continually fought against compromising his architectural vision in the face of various practicalities. Because he didn’t want any “ugly cooling towers” placed on his buildings, a specially designed water chilling plant (the largest one ever constructed) was built below street level which drew water from the Hudson. Yamasaki insisted on teak and highly polished steel for the elevator finishes, despite complaints from the operations team that such materials would be costly to repair when they were inevitably damaged. He only accepted the substitute of cheaper aluminum cladding in lieu of stainless steel for the building exterior when the supplier explained that aluminum could give him the desired color he was looking for (and even then, Yamasaki specified a solid aluminum panel which had to be specially developed by Alcoa).[8] Later, during construction, Yamasaki would complain that one of the panels was discolored, and demanded that several levels of steel be taken down to replace it (he backed down when it was pointed out that he was pointing to different panels each time he complained).

By most accounts, Yamasaki was extremely stubborn about these issues. When the operations team wanted to drop the 90-foot ceiling in the building lobbies by one foot to make it possible to clean the marble, Yamasaki argued against it for two years (the ceiling was ultimately lowered). And when the Port Authority insisted that the width of the windows be increased on the top floors to increase visibility, Yamasaki threatened to quit.

Continued opposition to the project

When the design for the trade center was unveiled in 1964, it unleashed another round of political obstacles that needed to be navigated. This time, opposition came from owners of New York real estate, who were worried about what 10 million square feet of space dumped on the market by an owner who didn’t have to pay taxes (and thus had structurally lower costs) would do to the real estate market. The most vocal of these was Lawrence Wien, who had recently purchased and renovated the Empire State Building. Wien organized the Committee for a Responsible World Trade Center, which spent the next several years opposing the project:

They took out a series of full-page advertisements in New York newspapers. They arranged for public hearings. They charged that the project was a real estate venture, that it was being built for profits to cover PATH’s deficits, that the agency’s figures relating to rentals were wrong, that the agency paid no taxes, that the towers would cause television interference, that traffic and transit would be impossible because of the large number of people at the site, and that the project would cost more per square foot than any other office building in history. At one point, Wien even suggested that the city was risking physical disaster such such a tall experimental design might fall or collapse.

The committee also directly lobbied the City of New York to oppose the project. The city leadership, notably mayor John Lindsay, was already miffed at the Port Authority for a number of reasons. The Port Authority had proceeded with such an enormous project without consulting the city, for one, and substantial tax revenues would be lost when the Port Authority took over a large area of Manhattan. Additionally, the Port Authority had (in Lindsay’s eyes) favored improving New Jersey’s port facilities over New York’s. Lindsay threatened to withhold the street clearing permits the project required, and this dispute wouldn’t be resolved until 1966, when the Port Authority agreed to various concessions to the City. In exchange for the permits, the Port Authority would increase its payments to the city to compensate for lost tax revenue, perform various city improvement projects (such as road widening and sewer renovation), build a $100 million passenger ship terminal, and use the excavated earth from the trade center site to create 23.5 new acres of new land (valued between $30 and $90 million) on the west of Manhattan, which would become part of Battery Park City.

Even after a deal was struck, Wien would continue to oppose the trade center. He filed a suit against the Port Authority in 1967 when it proposed moving the TV masts located on the Empire State Building (the leases of which were quite lucrative) to the World Trade Center. Wien's committee would continue to run ads against the project, including one notable one in 1968 that implied the completed trade center would be at risk of being struck by an airplane.

- ^

The department would also be responsible for managing the Port Authority’s contributions to the 1964 New York World’s Fair, which included selling more than 2 million square feet of transportation exposition space. The fair, which was held without the blessing of the Bureau of International Expositions, would ultimately lose millions of dollars, and lead to the downfall of Robert Moses (who had headed the project).

- ^

The World Trade Center by Anthony Robins

- ^

Johnson claimed to be an architect of the Seagram Building, but the owners of said building “made very strong statements to the effect that Mr. Johnson was not the architect of the Seagram Building, but was merely an associate to Mies van der Rohe.” (From The World Trade Center by Anthony Robins)

- ^

From Yamasaki’s letter to the Port Authority on his approach:

For your project, to me, the basic problem beyond the solving of the functional relationships of space is to find a beautiful solution of form and silhouette which fits well into Lower Manhattan and gives the World Trade Center the symbolic importance which it deserves and must have. In my opinion, this should not be an overall form which melts into the multi-towered landscape of lower Manhattan, but it should be unique, have excitement of its own, and yet be respectful to the general area. The great scope of your project demands finding a way to scale it to the human being so that, rather than be an overpowering group of buildings, it will be inviting, friendly, and humane. Its great spaces need the excitement and delight of change of pace, of surprise, of interest, to avoid the danger of an overwhelming multiplicity of repeated modules. To be symbolic of its great purpose, of the working together in trade of the Nations of the World, it should have a sense of dignity and pride, and still stand for the humanity and democratic purposes in which we in the United States believe.

- ^

The World Trade Center by Anthony Robins

- ^

The plaza would end up being closed for several months every year due to the risk of falling ice from the towers.

- ^

Today the firm is known as Magnusson Klemencic Associates, or MKA, and remains one of the premier structural engineering firms in the US.

- ^

From Yamasaki’s autobiography:

When the World Trade Center was being designed, Fritz Close, then chairman of Alcoa, called me one day and said, “Yama, I understand you are going to use stainless steel for the curtain walls of the towers.” I laughed and said I was thinking of it. He asked “Why? Aluminum is significantly cheaper.” So I told him that I did not like the color of standard aluminum, since it was so cold-looking. He said he could change the composition of the alloy and provide exactly the warm color of aluminum I wanted, using new technologies to overcome problems of color consistency from panel to panel. I told him I did not want a coating, but a new alloy to give us the color throughout the panel. He agreed, so Alcoa’s labs went to work and gave us several trials of pink, brown, and other shades

- ^